Dry All introduces a new way to install and connect Filter Driers on HVAC&R Lines!

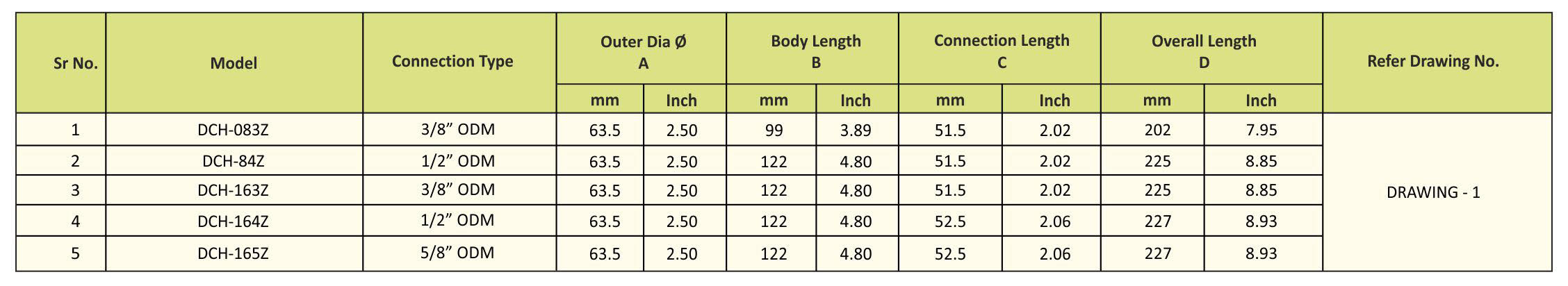

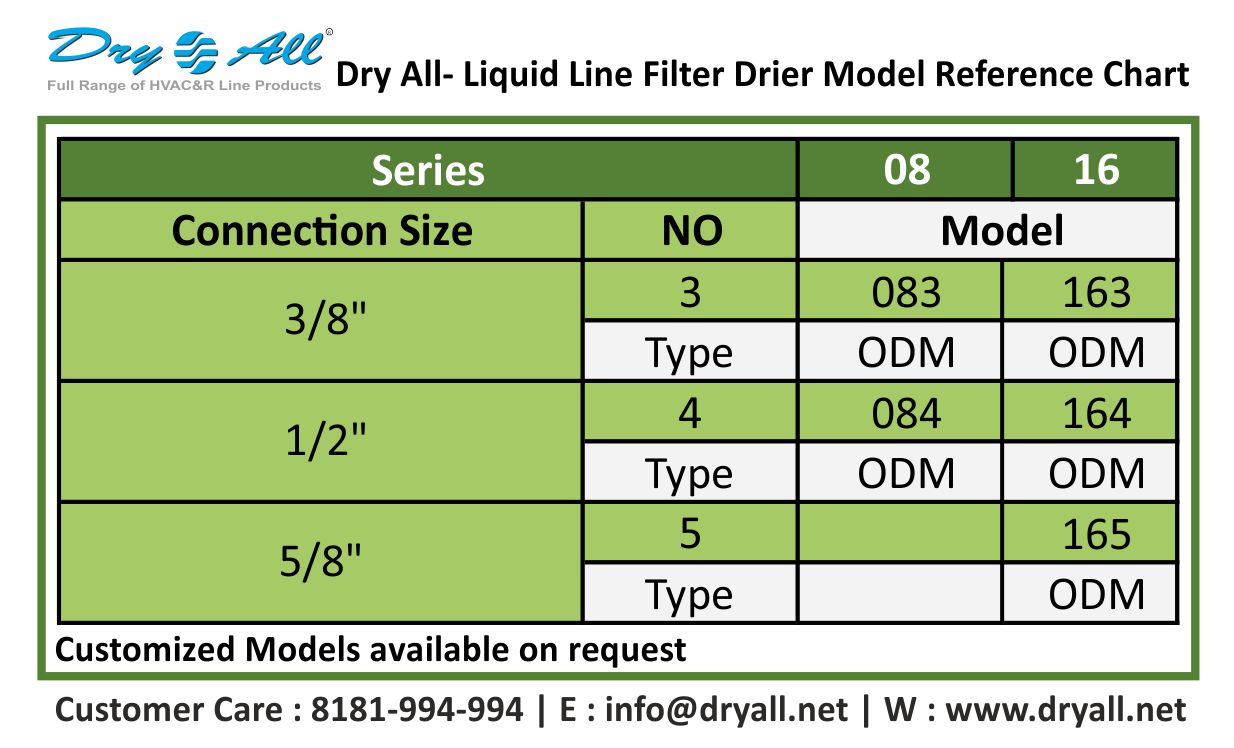

Dry All manufacturers complete range of Filter Driers to suit Press/Push Fittings available in the HVAC&R Industry today. These fittings require the copper connection sizes of the driers to be in ODM sizes and the same are available on a complete range of Dry All Filter Driers. Some models are available off the shelf and some can be made available as per order.

Press-to-connect or Push-to-connect or many such similar mechanical fitting is a new way to connect the HVAC&R components and lines. These refrigeration line fittings eliminate brazing, flames, fire spotters, or risks from installing traditional HVACR fittings.

HVAC&R professionals know that time is money. These Press/Push fittings offer a way for technicians contractors to connect refrigerant lines in seconds, boosting efficiency while providing the safety and reliability of a leak-free joint.

These Press/Push fittings or other option lets you make a permanent and reliable mechanical connection in just 10 seconds, without the need for brazing. That means significant time and cost savings. In fact, eliminating the brazing step means installation goes up to 60% faster!

Tube ends are made ready in nearly the same way as brazing, but the Press / Push tool does all the connection work in just a few seconds. This not only eliminates the time-consuming brazing process but also the time and effort of hauling heavy brazing equipment from job to job.

These fittings are ideal for Residential AC, HP, Mini-split, and Refrigeration installations.

Flame-Free

These Press/Push Fittings take the danger of an open flame out of the workplace, creating a safer work environment with no fire hazards. That means there’s no need for hot work permits, fire spotters, or fire-related safety equipment. ‘NO’ brazing also means no need to purge nitrogen, and no need to transport flammable gas and other brazing equipment to the job site.

As the use of flammable refrigerants in the HVAC&R industries continues to increase, the safety of flame-free Push/Press Fittings will become even more important.

Proven Reliability

The Push/Press Fitting connection process results in a repeatable and reliable mechanical joint every time – as well as a perfectly clean joint inside and out so there is no oxidization at the brazed joints. Press fittings have a proven track record of reliability, with many years of field use and millions of fittings installed worldwide. These fittings were specifically designed and engineered for use in high-pressure HVAC and Refrigeration systems. Some manufacturers have their fittings fully registered and listed to UL207 for pressures up to 700 PSI.

These Press/Push fittings virtually eliminating the chance of human error, and also result in less rework.

Higher Productivity

Converting from brazing to flame-free fittings can result in significant time and cost savings and substantially higher productivity. Eliminating the brazing process means installations can be completed up to 60% faster. The reduced labor costs – combined with the elimination of brazing materials and equipment, fire spotters, and hot work permits – results in far lower total installed costs when compared to brazing.

With Push/Press Mechanical Fittings, jobs can be completed successfully by fewer people in significantly less time. That not only results in increased productivity on each job but also the ability to get to the next job faster and get more jobs done.