Q. Why is Filter Drier is required in HVAC&R System?

A. Filter Drier is installed to protect the HVAC&R System from circulating solid contaminations, moisture and acids.

A Filter Drier will stop contamination from blocking the expansion device, prevent ice formation on the orifice of expansion valve and formation of acid by adsorbing moisture from the refrigerant

Q. How does a Filter Drier work and serve the purpose?

A. Filter Driers are exactly what they sound: Filter + Drier. The internal construction has filtration medium at inlet to filter contaminants, followed by desiccant as drying agent for moisture and acids. For in-depth cleaning, one more filtration layer is provided at the outlet.

The desiccant comprises of Molecular Sieve and Activated Alumina which will adsorb moisture and acid respectively in the system.

Final filtration is through a special filter element which can give filtration upto 20 microns.

Filter driers are able to trap and contain contaminants, moisture, acid and wax from circulating throughout the HVAC&R System.

Q. What are the different types of Filter Drier available in Dry All product range?

A. a) Liquid Line Filter Drier – DMH, DCH, DMHSG, DCHSG, DCHBF, RD and all of these with TW (Leak detection Technology)

b) Suction Line Filter Drier – DCHSF

c) Suction Line Filter – DSF

d) Semi-Hermetic -DRC Series with replaceable Core type DC-48, DA-48, DB-48 & DC-100 for Liquid Line and replaceable Filter DPE-48-BD, DPE-100-BD, DSS-48, DSS-100 for Suction Line

Q. Where is Filter Drier installed in HVAC&R system?

A. Liquid Line Filter Drier is installed in the liquid line of the HVAC&R System, after the Receiver and before expansion device such as Capillary, Thermostatic Expansion Valve or Electronic Expansion Valve.

Filter Driers called Suction Line Filter Driers are also available for suction line of the HVAC&R System. These are installed after the evaporator and before the accumulator or compressor.

Q. What is the primary difference between Dry All – DMH & DCH Drier Series?

A. Dry All is the only company which offers both desiccant technology of Bead Type & Solid Core Type Drier.

In DMH Series – Bead Type Technology, desiccant in bead form comprising of Molecular Sieves (70%) and Activated Alumina (30%) is spring loaded between perforated plate and filters. This series also has unique feature of filtration at both inlet and outlet.

In DCH Series – Solid Core Technology, desiccant comprising of 80% Molecular Sieves and 20% Activated Alumina is molded into a solid core and used as desiccant medium.

Q. Which one is a better Drier – DMH or DCH Series?

A. Both technologies are well accepted worldwide. But with advent of new refrigerants and change in technology, it is observed that DMH Series (Bead Type Filter Driers) offer better results in terms of contamination control, moisture adsorption and controlling acid formation.

We have seen better test results in DMH Series Filter Drier, both during lab testing and field trials.

Q. In what different volume and connection size range are Dry All Filter Driers available?

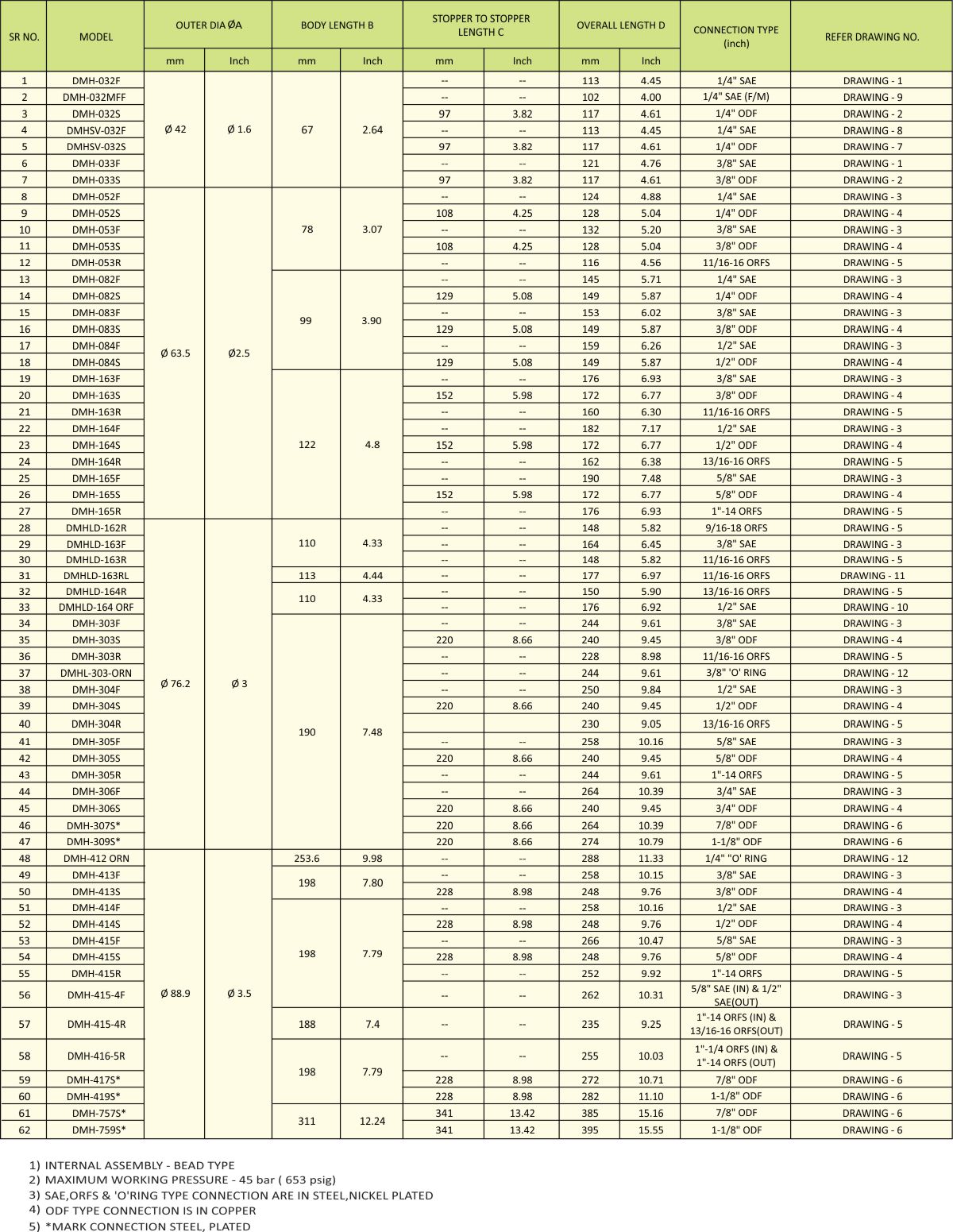

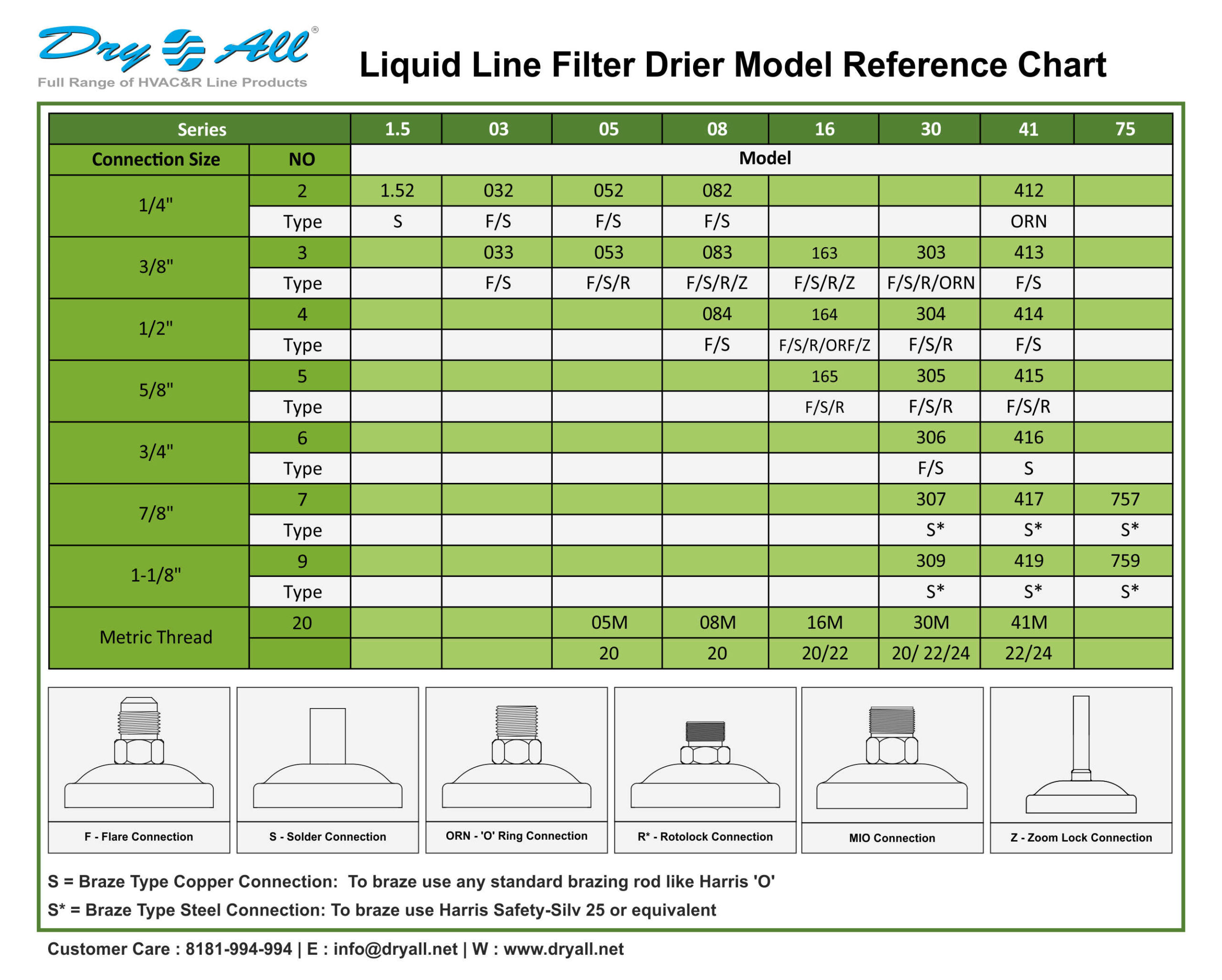

A. Dry All Filter Driers are available in 1.5, 3, 5, 8, 16, 30, 41 & 75 Cubic Inch desiccant volume.

Dry All hermetic Filter Driers are available from 1/4″ to 1-1/8” connection sizes.

Semi Hermetic Filter Driers (Core Shells) are available in 1, 2, 3 & 4 Core Series. Connection sizes is available from 5/8” to 3-3/8” connection.

Q. What are the different types of INLET and OUTLET connections available on Dry All Filter Driers?

A. Dry All offers the following connections:

| Connection |

Denoted by Alphabet / s |

| Flare or SAE |

F |

| Solder or ODF or Braze |

S |

| O-Ring Face Seal (Rotolock) |

R |

| Zoom Lock |

Z |

| Male Insert O-Ring |

MIO |

| O-Ring Flare |

ORN |

Which series of drier is available in which connection sizes and types is clearly shown in model selection chart on our website – www.dryall.net

Q. What factors are taken into consideration while selecting Filter Drier model?

A. Drier sizing should take into account both the volume of refrigerant in the system and the pressure drop across the drier. In general, driers should be sized for a pressure drop of 1 psig or less.

To select a suitable drier for a specific system, first consider the tube diameter of the liquid line or suction line on which the drier has to be installed.

As there are usually several filter sizes available for a given connection diameter, the drying capacity should be next selection criteria.

For quick selection in consideration of the drying capacity or liquid capacity, one should always choose a slightly larger drier. For example, if the connection line is 3/8” the following drier model DMH 033, DMH 053, DMH 083, DMH 163 and DMH 303 are all 3/8” connection. For a rough selection, you should always favor the next larger size but keeping an eye on pressure drop.

Q. What is the Maximum allowable pressure / Maximum Working Pressure of Dry All Filter Driers?

A. Dry All Filter Driers are available with MWP as 653 psig (45bar).

Q. Are Dry All Filter Driers UL Listed

A. Yes, complete range of Dry All Filter Driers are UL listed.

The UL File number is SA33181-20140331 and the certificate can be viewed on our website.

Q. 1Does Dry All make customized Filter Driers?

A. Filter Driers are pretty universal, off-the-shelf product and normally does not require any customization. However, we can make customized Filter Driers as per customer design and specification. Please contact Dry All for more details on the process, models available, MOQ, price, etc.

Q. Does Dry All Filter Driers come with in-built Sight Glass?

A. Yes, we have Filter Drier with inbuilt Sight Glass -DMHSG & DCHSG Series. They have a great advantage of space reduction, reduced cost, ease of installation and aesthetic improvement

Q. Does Dry All Offer Filter Driers with in-built Schrader Valve?

A. Yes, Dry All offers many models with Schrader valve. The 032 Models with inbuilt Schrader valve are a popular product. Please contact Dry All for more details, models available, MOQ, Price, etc.

Q. What is the specialty of Suction line Filter driers DCHSF Series?

A. Dry All DCHSF Suction Line Filter Drier comprises of a solid core as the desiccant medium. This solid core is made of 70% Molecular Sieves, 25% Activated Alumina & 5% activated carbon.

These driers are used for system clean up when there has been a burnout or when major work has been performed on the system and an addition check is required.

Schrader Valve are provided at both inlet and outlet of the suction filter. This is to permit pressure drop reading during the clean-up. Inlet Schrader valve can also be used for charging of refrigerant, to take care of contaminates in the refrigerant if any.

Q. Where is the Suction Line Filter Drier Installed? Do we need to install Suction Line Filter Driers before the Compressor?

A. Suction Line Filter-Driers and Suction Filters should be installed as close as possible to the compressor and before the accumulator. If a suction vibration eliminator is used, the drier or filter should be installed upstream of it.

Q. What is the purpose of Suction Line Filter?

A. Dry All DSF Suction Line Filter Series is used in the suction lien of a HVAC&R System, for the purpose of removing and retaining solid contaminants from the Refrigerant with lowest pressure drop.

The internal construction comprises of no desiccant but a pleated filter made of special paper. The flow velocity of the Suction Filter does not act as oil trap and hence proper oil return is obtained.

Schrader Valves are provided at both inlet and outlet of the suction filter. This is to permit pressure drop reading during the clean-up. Inlet Schrader valve can also be used for charging of refrigerant, to take care of contaminates in the refrigerant if any.

Q. What is Bi Flow Filter Drier?

A. Dry All DCHBF Series Filter Drier is a Solid Core type Filter Drier, designed especially for use on Liquid Line of Heating & Cooling machines.

These driers are usable in both directions. In a machine which is used for both Heating and cooling, flow direction will happen on both the direction.

Q. Does Dry All have Driers for Bus Air-conditioner & Truck Refrigeration?

A. Dry All offers wide range of Filter Driers for above application with special connections to withstand high vibration. Please check section on this on our website.

Q. Which unique Filter Drier technology has been innovated by Dry All?

A. Dry All has tied up with Spectroline-USA to manufacture world’s first and only Filter Driers with inbuilt leak detection technology. These driers are called TW Series. Please refer to our website for more details. We have a separate section on this product line with complete FAQ, just on this TW technology.

Q. What is the best way / practices to install a Filter Drier?

A. Please scan the QR Code provided on the drier packing to find all instructions on installation of Filter Driers. The instructions cover both braze type or threaded type of driers. It also has details on the TW series of driers

Q. What happens if we install a Filter Drier backwards?

A. Each Dry All Filter Drier comes with a clearly marked arrow showing the direction in which the Filter Drier has to be installed. If installed backwards, the Filter Drier will not work and will have to be removed immediately.

Q. What is the lifetime of a Filter Drier?

A. HVAC&R systems are closed loop; hence it is not necessary to replace Filter Driers periodically unless one sees a drastic pressure drop between the inlet and outlet of the Filter Drier. The other reason to change filter drier is when the sight glass shows presence of moisture. This means that the drier is now saturated and can now cannot handle any more moisture.

Note: It is strongly recommended that one should change the Filter Drier every time the unit is opened up for servicing or after any other component change.