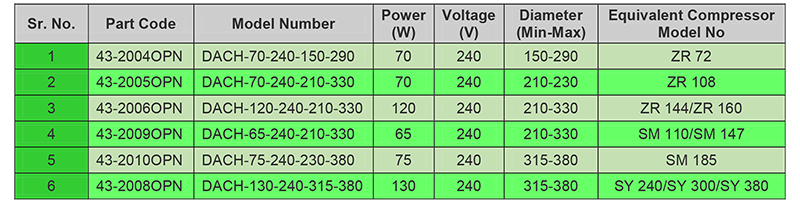

1. What is a crankcase heater?

In refrigeration and air conditioning systems, maintaining the proper flow of refrigerant within the compressor is crucial for optimizing performance and extending the compressor’s life. One common challenge is preventing the mixing of lubricant oil and liquid refrigerant which can lead to internal damage and reduced efficiency. To overcome such issues crankcase heater is used.

2. How does a crankcase heater work?

A crankcase heater is used to prevent refrigerant from migrating into the shell during the standstill period. They feature a heating element that’s powered by electricity, electricity helps the crankcase heater to produce heat. Crankcase heater brings the fluids to its operating temperature before starting, the compressor motor can start easily where it left from.

3. Why is the installation of a crankcase heater along with compressor is important?

The crankcase heater keeps the refrigerant warm and above the refrigerant boiling point and also keeps the oil in the compressor warm. Without the crankcase heater the compressor would have to work a lot harder during startup which causes wear and tear to the internal parts of the compressor.

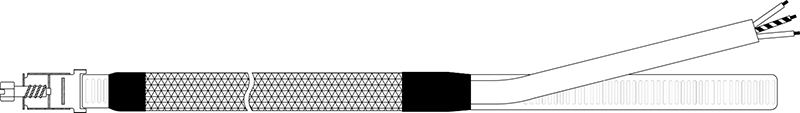

4. How do I select right crankcase heater for my compressor?

Available models of Dry All crankcase heater are mentioned in the catalogue along with its equivalent compressor model no, required wattage and voltage.

5. What if more than rated voltage is given to Dry All crankcase heater?

Dry All crankcase heater should be given only its rated voltage, more than rated voltage can cause damage to the component.

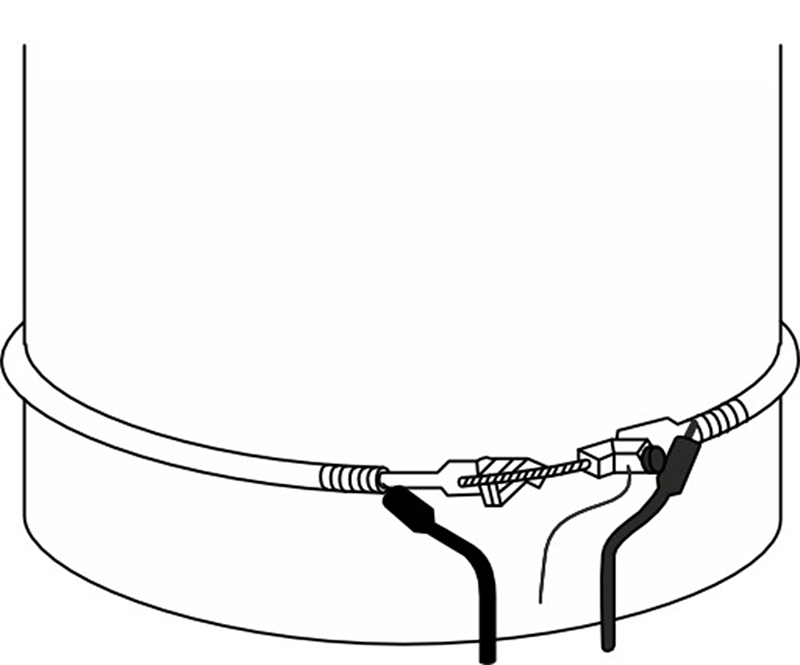

6. What is the installation criteria for Dry All crankcase heater?

Dry All crankcase heater should be installed minimum at a height of 50mm from the compressor base (Disc)