FAQ: ‘Dry All’ Liquid Refrigeration Receivers

- Why a Liquid Refrigerant Receiver (Receiver) is required in HVAC&R System?

Receiver is a storage vessel designed to hold excess refrigerant which is not in circulation. Refrigeration systems exposed to varying heat loads, or systems utilizing a condenser flooding valve to maintain a minimum head pressure during low ambient temperatures will need a receiver to store excess refrigerant.

Receiver also plays a key role in a HVAC&R system as it ensures that only liquid refrigerant should enter the expansion device.

Due to density difference during cycle operation, liquid refrigerant is accumulated at the bottom of the receiver and remaining volume is occupied by the vapor refrigerant.

Receiver also acts as a reservoir during system pump down.

- How does a Receiver work and serve the purpose?

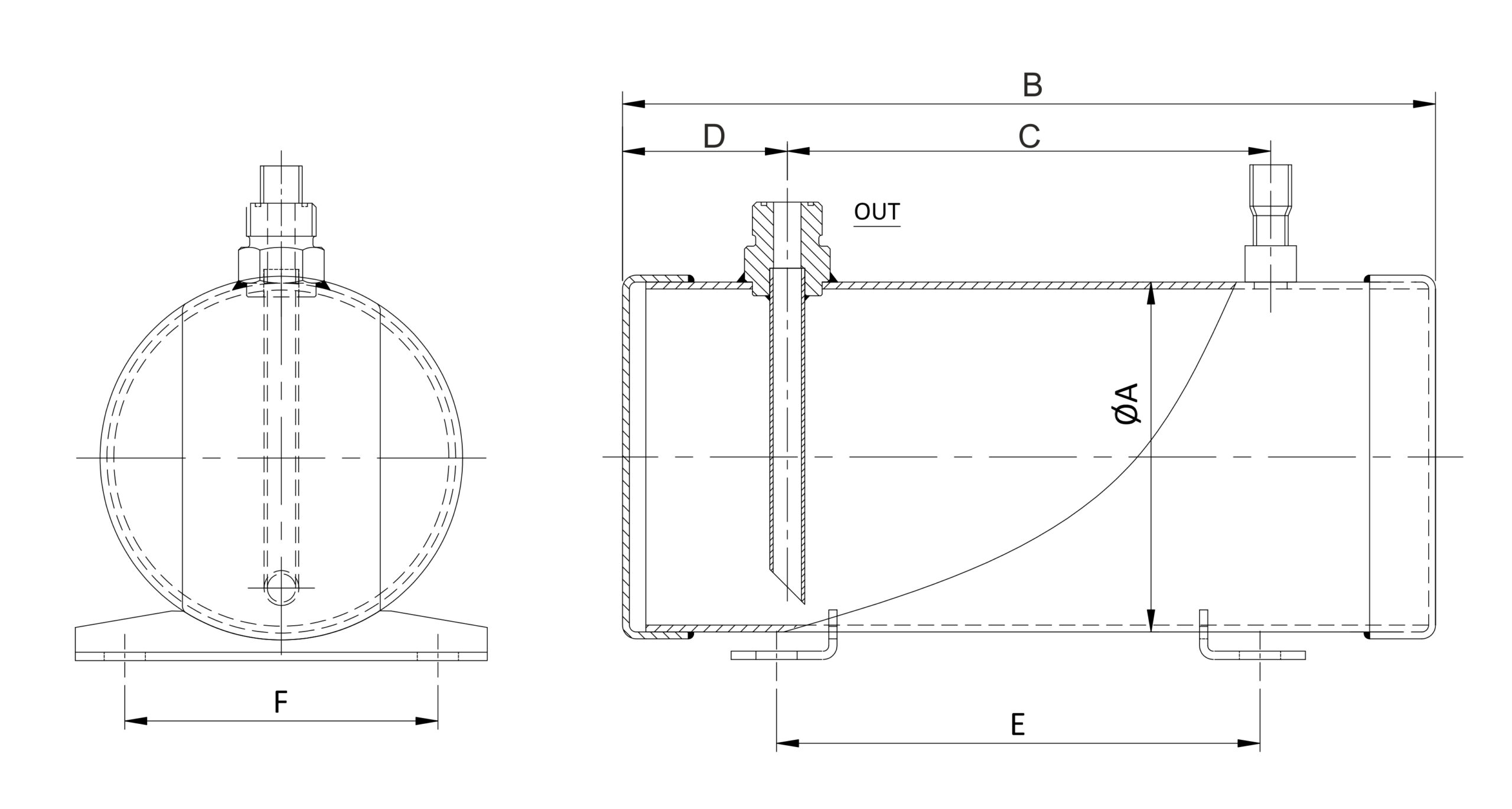

Liquid + Vapor refrigerant will enter the Receiver from ‘Inlet’ which is normally at the top / upper side of the receiver and is free flowing. The vapour will be always at the top and liquid at the bottom of the Receiver. The outlet connection of the Receiver is through a dip tube of which the pickup point is at the lowest level of Receiver. This dip tube will always pick up only liquid from the bottom of the Receiver.

- Where is Receiver installed in HVAC&R system?

The receiver is installed in the liquid line (i.e. the part of the refrigeration cycle where the refrigerant is in the liquid phase) and is located after the condenser in a refrigeration system. It is installed between the condenser and the liquid line filter drier.

- What are the different types of Receivers available in Dry All product range?

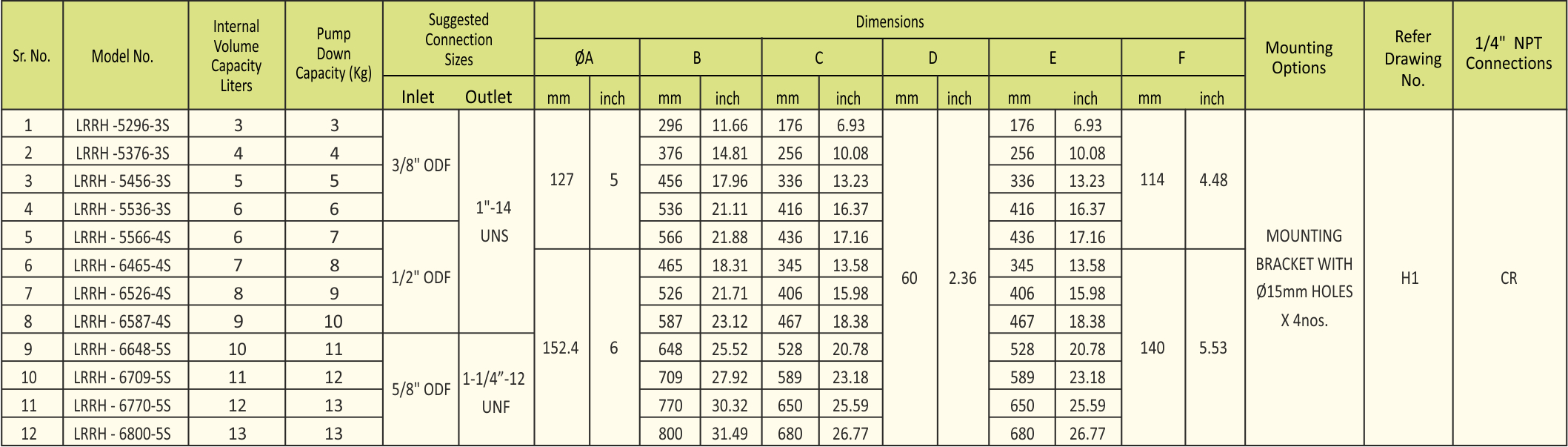

We have both Vertical and Horizontal type Receivers.

- How do you select a Receiver Model?

First, one has to check the volume / holding capacity required. Receivers holding capacity is typically selected @110 % of total refrigerant charge. For example, if the refrigerant charge is 10 Kg, the receiver should have holding capacity of 11Kg. One has to also consider the Condensor size while calculating the receiver volume. Receiver inlet and outlet connection sizes should be in-line with the system liquid line tubing sizes.

Please consult the Dry All team before selecting the model.

- In what capacity range are Dry All Receivers available?

Dry All receivers’ off-the-shelf models are available from 1 Litre -25 Litre capacity. Customized models are available from 1 Litre – 50 Litre capacity.

- What are the different types of INLET and OUTLET connections available in Dry All Receivers?

Solder & Roto-lock type connections from size 3/8” to 1-3/8” are available. Please refer Dry All catalog for more details.

- What is the Maximum allowable pressure / Maximum Working Pressure of Dry All Receivers?

We have Receivers available with MWP ranging from 31 bar – 45 bar.

- What are types of mounting / Fixing available in Dry All Vertical Type Receivers?

Two type of mountings are available:

a) Bolted & Nut (Stud type)

b) Mounting Flange

- Does Dry All Receivers come with Sight Glass?

Models ranging from 15 Litre to 25 Litre come with sight glass.

- Does Dry All Receivers come with provision for Fusible Plug / Pressure Relief Valve?

This provision is available on our LRRVD* Range of Receivers from 6 Litre – 12 Litre models only. *LRRVD-Deep Draw Type Receivers. This feature can be provided on all customized models. When system temperature or system pressure goes extremely high, a fusible plug / pressure relief valve respectively prevents the liquid receiver from bursting.

- Do you make customized Receivers?

Yes, we make customized receivers as per customer design and specification. Please contact Dry All for more details on the process, models available, MOQ, Price, etc.