1. What is a coaxial heat exchanger?

Ans: A coaxial heat exchanger is a type of tube heat exchanger used in various applications like heat pumps, marine air conditioners, swimming pools, and water chillers. It is primarily used as a condenser or evaporator and features a tube within a tube structure.

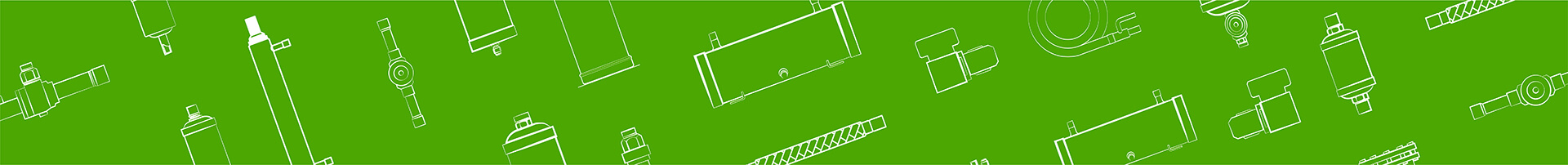

2. What is the structure of a coaxial heat exchanger?

Ans: A coaxial heat exchanger has a “tube in tube” design. The outer tube is typically made of steel or copper, while the inner tube can be titanium, copper, or copper-nickel. The inner tube’s surface often has spiral grooves to enhance heat transfer.

3. How does heat exchange occur in a coaxial heat exchanger?

Ans: In a coaxial heat exchanger, water flows through the inner tube while refrigerant flows between the outer and inner tubes (refrigeration loop). Heat transfer occurs as the temperature difference between the refrigerant and water causes heat to transfer from the higher temperature source to the lower temperature source, typically in a counterflow configuration.

4. What are the applications of Dry All coaxial heat exchangers?

Ans: Dry All coaxial heat exchangers find applications in HVAC systems, cold/cold chain processes, food and household appliances (such as water purifiers, ice makers, washing machines, dishwashers, and milk cooling equipment), titanium alloy applications, ships/transportation, energy/power generation, oil & gas exploitation, aerospace, and chemical/pharmaceutical industries.

5. What are the advantages of coaxial heat exchangers?

Ans: a) Concise and clear structural features with modular design and easy adjustment.

b) Can be customized to fit specific needs, including different shapes (rectangle, round, double helix, spiral, trombone, etc.).

c) High heat exchange efficiency due to pure counterflow design and embossed inner tube surface enhancing heat transfer.

d) Few solder joints, resulting in increased reliability.

e) Good freezing resistance, reduced scaling, and long service life.

6. What is the maximum working pressure?

Ans: On Refrigerant side: 42 bar, On Water Side: 15 bar

7. Can we use Coaxial for seawater application?

Ans: Yes, we offer Titanium Tube Coaxial Heat Exchangers specifically designed for marine applications.

8. Can we use Coaxial Heat Exchanger for food application?

Ans: Yes, we have Stainless Tube Coaxial Heat Exchangers suitable for food-grade applications.

9. What are the different types of coaxial heat exchangers available with Dry All?

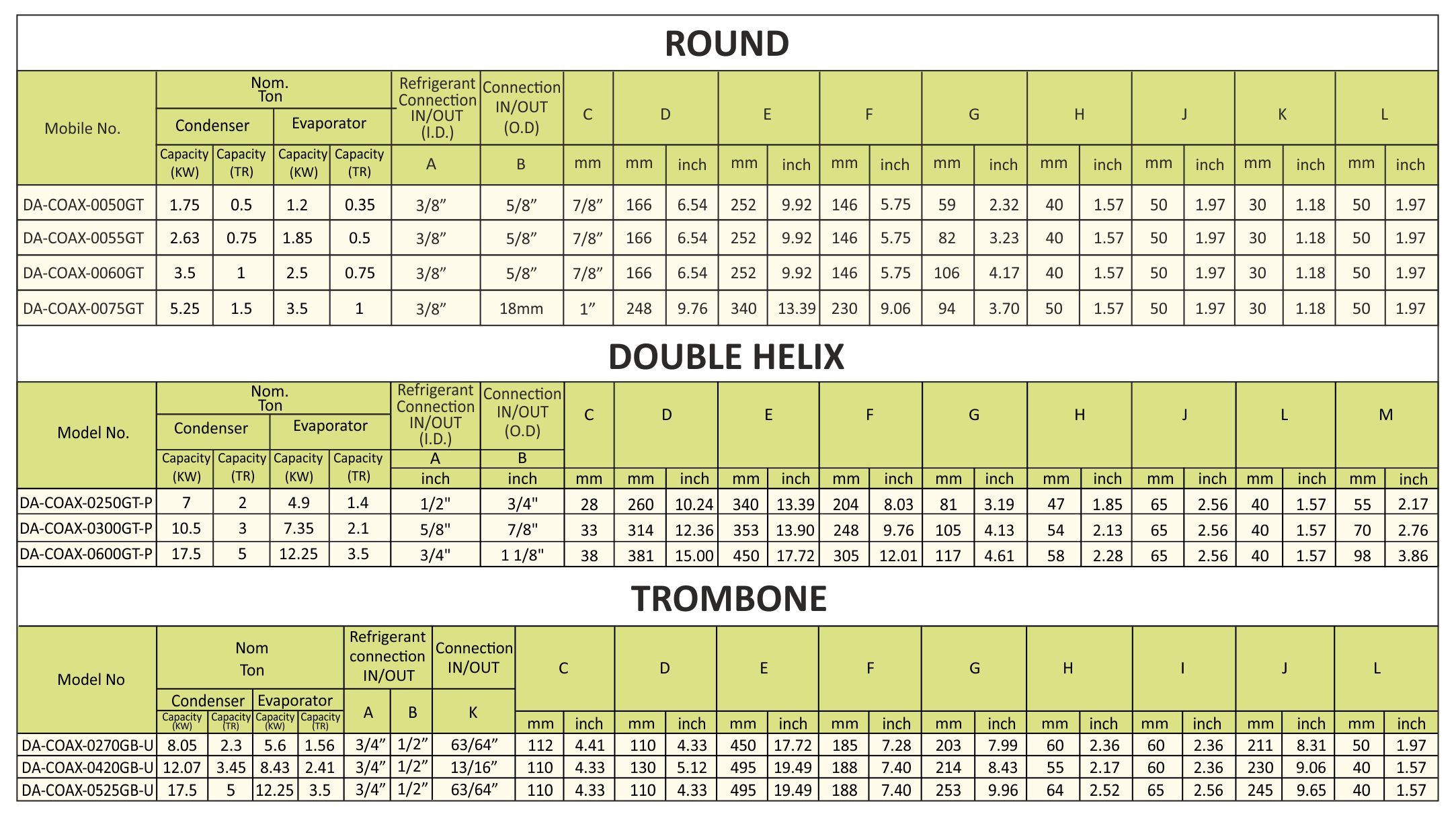

Ans: We offer Round, Trombone, and Double Helix types of coaxial heat exchangers.

10. What are the different tonnage options available with Dry All?

Ans: We have condenser models available in stock ranging from 1TR to 6.5TR.

11. Can a coaxial heat exchanger be used as both a condenser and an evaporator?

Ans: Yes, a coaxial heat exchanger can be used as both a condenser and an evaporator.

12. Can Dry All provide insulation for the coaxial heat exchanger?

Ans: Yes, if required, Dry All can provide insulation for the coaxial heat exchanger.