FAQ – ‘Dry All’ Oil Separators

<br.

- Why an Oil Separator is required in HVAC&R System?

During functioning of the compressor, some amount of oil in the crank-case of the compressor will also boil off along with the refrigerant and escape the compressor. If this oil is not returned back to the compressor, the compressor will cease due to lack of lubricating oil.

Secondly circulating oil in the system will form a coating on the system components and affect heat transfer and hence reducing the efficiency of the system.

The oil which has escaped needs to be returned back to the compressor with the help of an Oil Separator.

- How does an Oil Separator work and serve the purpose?

Oil separators separates oil from the hot vapour refrigerant in the discharge line, temporarily store the oil, and then return it back to the compressor crankcase or to the oil reservoir in multiple compressor systems, thus assuring an efficient lubrication of compressors moving parts.

When mixture of refrigerant and oil enters the Oil Separator inlet, the same passes through a fine steel mesh filter pocket. This disturbs the mixture and because of their individual properties they separate. Oil being heavy drops to the bottom. Refrigerant because of the vessel volume of Oil Separator will vaporize and will leave through the outlet pocket. Here too there is a fine steel mesh filter pocket which further stops the oil from leaving the Oil Separator.

- How is the collected oil returned back to the Compressor?

When the level of oil gets high enough to raise the stainless steel float ball, the oil return stainless steel needle valve opens up and the oil is returned back to the compressor crankcase through a small return line connected to the compressor crankcase.

The pressure difference between the high and low sides of the refrigeration or air conditioning system is the driving force for the oil to travel from the Oil Separator to the crankcase. When the oil level in the sump of the Oil Separator drops to a certain level, the float will force the needle valve closed.

- Why do we need additional Oil charge in an Oil Separator?

There is gap between Oil return orifice and shell bottom line. This volume is called dead oil volume which needs to be filled up by charging additional oil.

Before proceeding with the installation, the Oil Separator must be charged with a certain amount of oil in order to actuate the float mechanism immediately after start-up.

Failure to pre-charge separator sump may result in damage to the oil return float mechanism.

- How is additional oil charged in the Oil Separator?

Charge additional oil through ‘outlet’ connection of the Oil Separator before brazing the system tubing.

The oil grade will be always same as the compressor oil.

- Where is Oil Separator installed in a HVAC&R System and Why Oil Separator should be placed as close as possible to the Compressor?

Oil Separator should be placed as close as possible to the compressor for following reasons:

- To avoid major velocity drop

- To ensure the refrigerant gas will not condense in low ambient conditions.

- What are the different type of Oil Separators available in Dry All Product range?

The off-the-shelf models available are Float Valve Type Oil Separator and which are most popular.

The other type of Oil Separator available off-the-shelf is Multi Tube type coalescent Oil Separators.

In customized models we offer many variations such as Demister Pad type, Centrifugal Type etc.

These above oil separators work on various modes of oil separation methods such as reduction of velocity (Screen filtering), impingement, centrifugal action & coalescing elements.

- How do you select an Oil Separation Model?

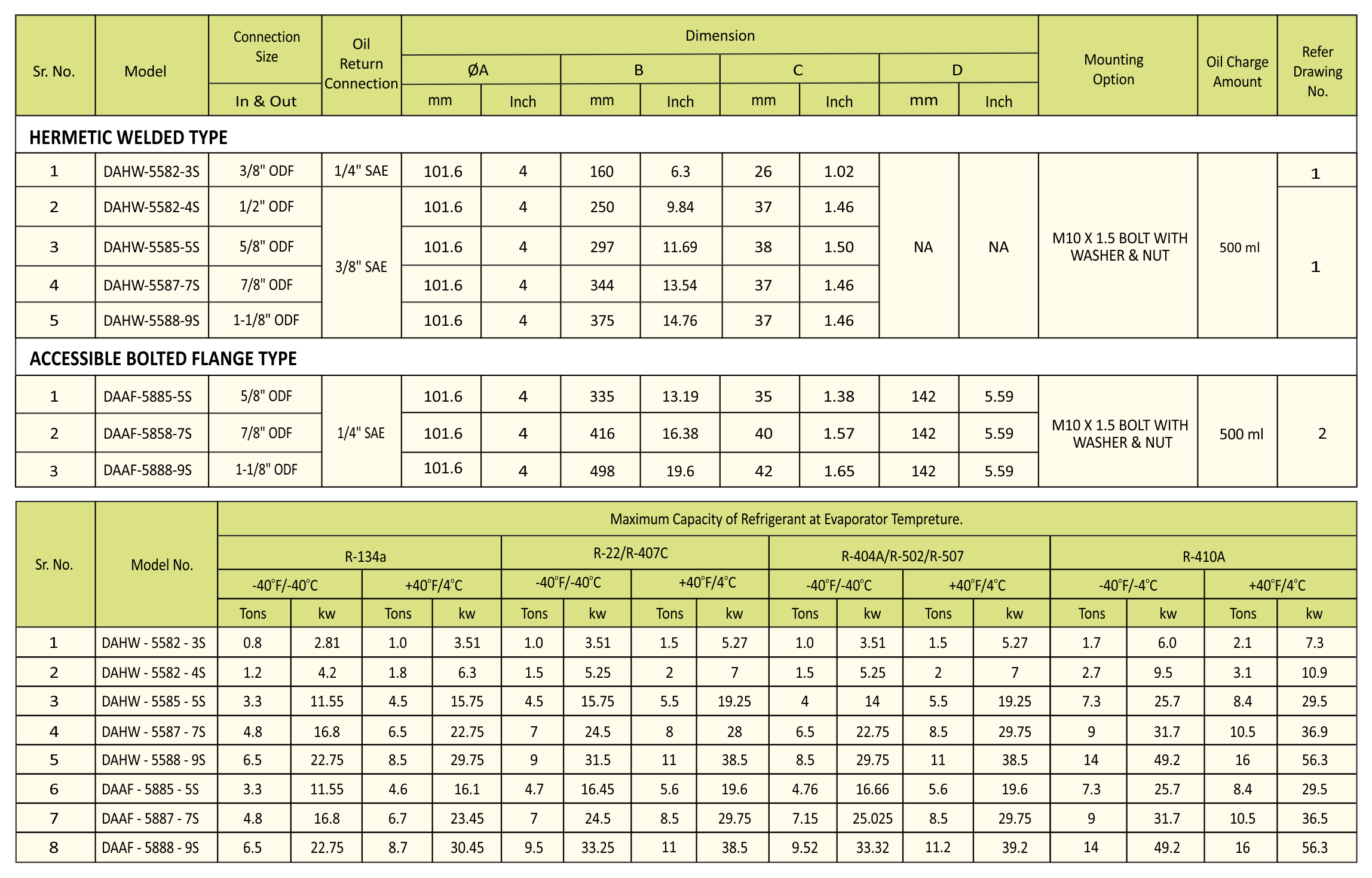

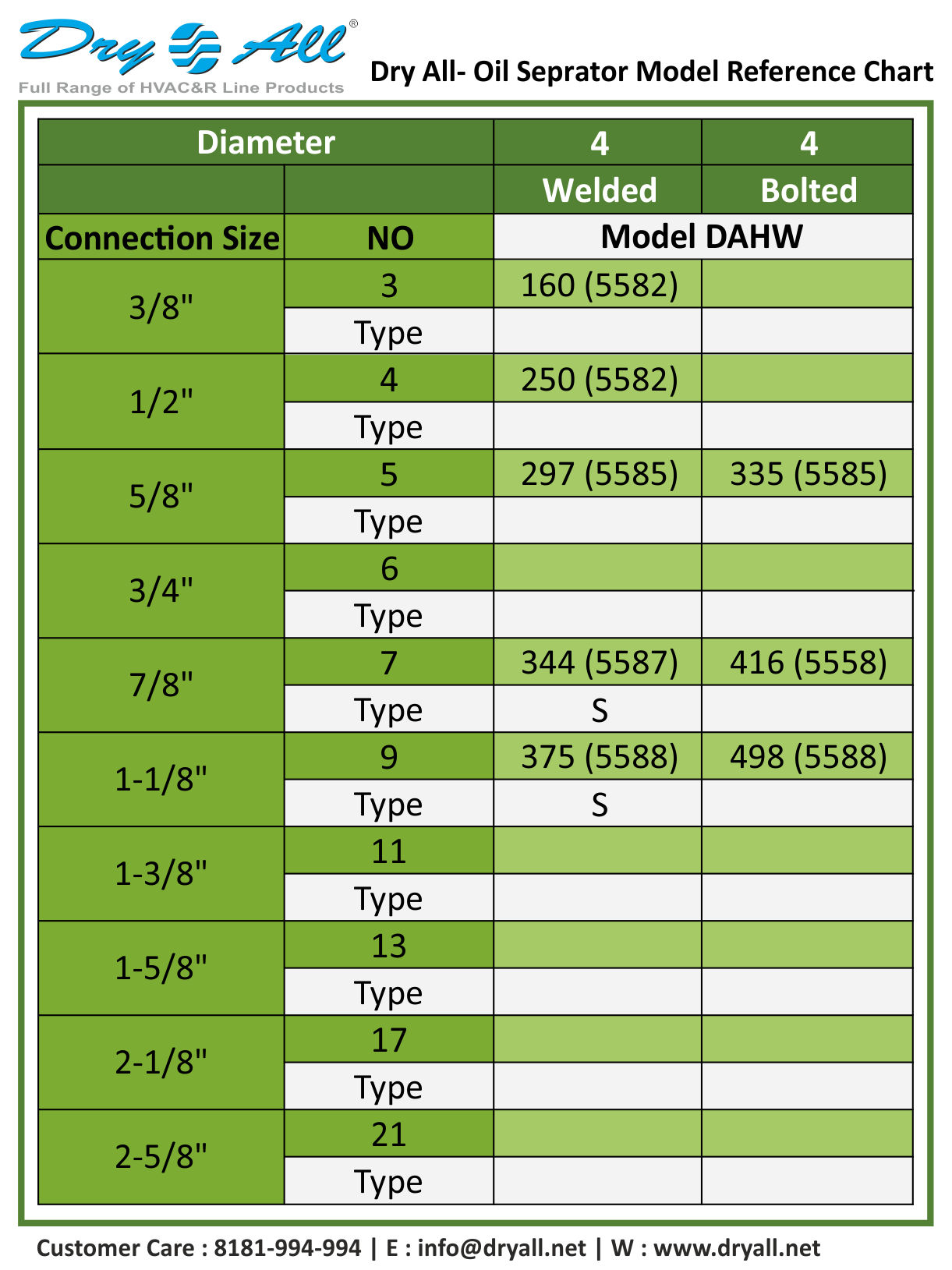

Oil Separators selected based on Refrigerant and Evaporation temperature of the system. Please refer to our product catalog for selection of right model.

- In what capacity range Dry All Oil Separators available?

Dry All off-the-shelf Oil Separator models are available from 7.3 kw to 56.3 kw for R-410A @4ºC Evaporation temperature. For other refrigerants and different evaporative condition, please refer to our catalog.

- What are the different types of INLET and OUTLET connections available in Dry All Oil Separators?

Connection size available from 3/8” to 1-3/8”.

- Do we need Sight Glass in Oil return line?

Yes, you may add a Sight glass in Oil return line which can be helpful in determining that oil is flowing back to the compressor.

- Do we need capillary in Oil return line?

Yes, you may have to add a calculated capillary tube in oil return line if suction gas temperature is going beyond compressor envelope.

- Why do we need to insulate the Oil Separator?

The oil return line from the Oil Separator to the crankcase should always be just above room (ambient) temperature. But if the Oil Separator is located in a low ambient area the discharge refrigerant gas may condense within the oil separator.

If the oil return line is cool or cold when touched, there may be liquid refrigerant vaporizing in it as it passes oil. This problem can be because of oil separator’s shell not being insulated or poorly insulated and becoming too cool. If the shell is too cool, it can cool discharge gasses too much, resulting in condensed (liquid) refrigerant at the bottom of the oil separator. This will cause the float to rise too often because of increased levels of an oil and liquid refrigerant mixture in the bottom of the separator.

Once the float rises and the orifice opens, the mixture of liquid refrigerant and oil passes through the oil return line. The liquid refrigerant will vaporize from the sudden pressure drop and cause the cool temperatures in the return line.

In such case the OS should be insulated to keep them hot during the on and off cycles. This will prevent refrigerant from condensing in them and mixing with the oil in their sumps.

- If I don’t install an Oil Separator, what is the effect of excess circulating oil on Thermostatic Expansion valve.

Most control valves, including TXV and capillary tubes will experience inefficient performance due to the pressure of oil filming.

Capillary tubes may experience wide variation in flow rates. Usually, reduced refrigerant flow rates may result in high head pressures and low suction pressures. TXV remote bulbs may not sense the correct refrigerant temperature at the evaporator outlet, causing improper superheat control. TXV hunting can also occur.

- Why connection size of Oil Separator should be same as compressor discharge line size?

Oil separator connection sizes must be the same or larger than the discharge line size of the system. This allows the discharge gases in the Oil Separator to be near the same pressure as the discharge line because of minimal pressure drop within the Oil Separator.

Never use undersized oil separator in terms of volume. It will lose its ability to return oil and will cause high pressure drop and hence causing system inefficiencies.

- What are the detrimental effects of oil in a HVAC&R System?

Oil that escaped the compressor and moved into the system, will deprive the compressor crankcase of its lubrication. The escaped oil will coat the walls of the condenser and evaporator and will reduce their heat transfer abilities.

If an oil separator is not installed, the compressor often sees slugs of oil that are returning from the evaporator. The compressor’s pistons can momentarily pump slugs of liquid oil that can build tremendous hydraulic forces because of the incompressibility of most liquids. Serious compressor valve and drive gear damage can result.

Oil separator maintains a high coefficient of condenser and evaporator performance by almost completely removing oil deposits from their exchange surfaces & limit accumulates of oil at Sensitive System Components.

- Do we need to replace Oil Separator after a system burn out?

It is recommended that after a burn out the Oil Separator must be replaced along with the filter driers.

- Do we need a Vibration absorber before an Oil Separator?

To protect the Oil Separator against vibration and gas pulsation generated by the compressor. Install a vibration absorber and muffler between the Compressor and the Oil Separator.